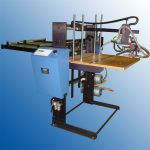

Description

Double Kote High Speed Lamination System Features

- Increased flexibility with stock sizes. Sheets from 8.5″ x 11″ up to 31″ x 40″.

- Patented NT Rollers preheat without water or oil which make them virtually “maintenance free”.

- Sheet feeder delivers a consistent gap ensuring an accurate process from start to finish whether using the Accu II HS cutter or going inline into a die cutter.

- 2″ diameter heated nip rollers allow for excellent bond with 1.3 – 15 mil films on litho prints.

- Dual fan banks and a chill roller provide web cooling for excellent clarity and cleaner cuts, even on thick films at high speeds.

Double Kote High Speed Lamination System Specifications

- Laminator Dimensions: 5′ W x 24′ 5″ L x 5’2″ H.

- Clearance: 5′ all sides.

- Laminator Electrical: 230V 80 amp 3 phase (w/ neutral and ground).

- Air: 12 cfm @ 100 psi.

- Warmup Time: 15 minutes.

- Pre Heat Running Temp: 70°-300° F.

- Nip Roller Running Temp: 70°-250°F.

- Lamination Films: PET, OPP, PVC.

- Film Loading Times: 3 – 5 Minutes.

- Max Laminating Film Roll Diameter: 18″.

- Laminating Film Thickness: 1.3mil – 15mil.

- Max Laminating Film Roll Weight: 150 lbs.

- Max Laminating Film Roll Width: 31″.

- Min Cut Sheet Size: 8.5″ x 11″.

- Max Cut Sheet Size: 31″ x 40″.

- Min Substrate Weight: 80 lbs text.

- Max Substrate Weight: 20 pt board.

- Sheet Feeder Pile Height: 29″.

- Lamination Speed: up to 125 fpm (feet per minute).

Click here to download Double Kote High Speed sales literature

Made in the USA

Made in the USA