A Three Layer Card That Costs Less, Totally Secure with Totally Sustainable Content.

“Impossible,” you say.

Read This:

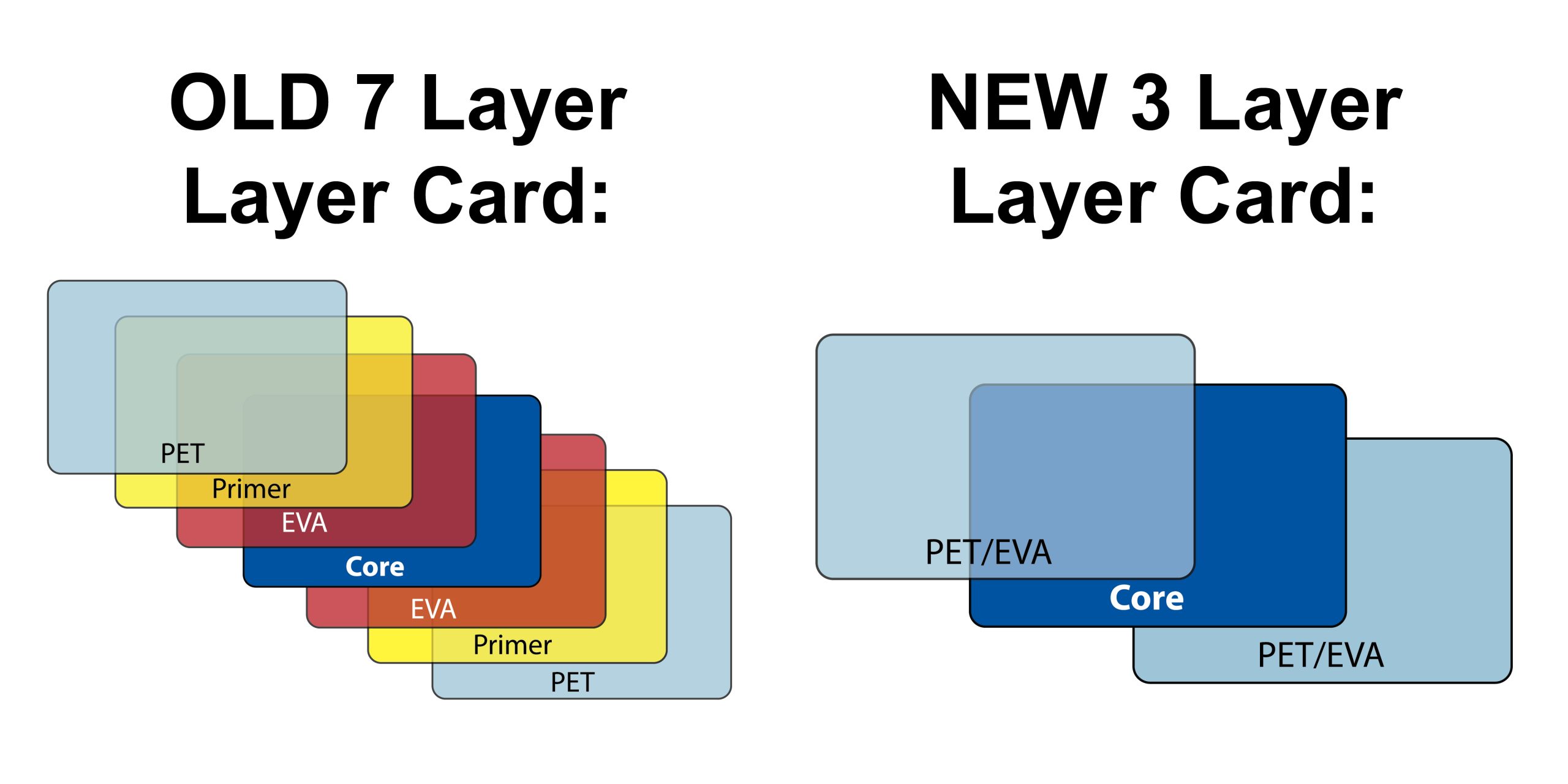

The old Polyester/EVA/Teslin card was made up with seven layers. Trying to stick seven layers together and maintain a secure, tamper-proof card was a difficult and expensive process.

Today that card can be assembled with only three layers. The polyester outside layer is produced in one layer with polyester on one side and EVA on the other.

Eliminating the interface between these two films saves the cost of security seals and provides total intrusion-resistance.

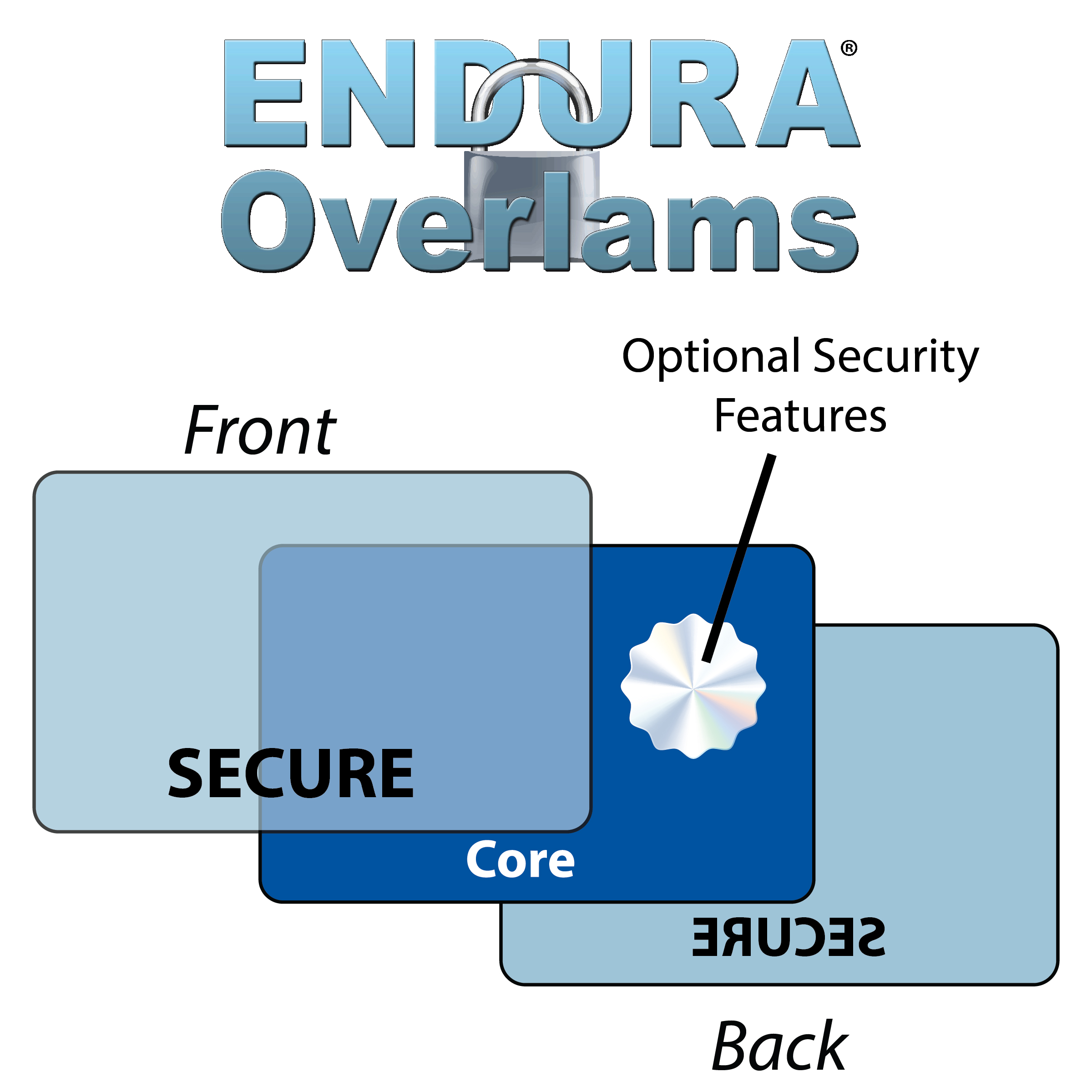

All that’s required with ENDURA OVERLAMS® is a printed core material, some security seals on the core or the laminate, and a platen press or a laminator.

The result is a card that’s less expensive and totally counterfeit-proof. Using UV-protected polyester increases card life from 5 years to 10 years.

The extrusion coating process used to produce thermal laminating film creates tons of scrap.

This polyester/EVA scrap can be ground to a fine granular powder and used as an additive for other plastics used in fencing, deck boards, furniture, and even tennis shoe soles. The EVA blend acts as a glue to hold all ingredients together.

Click here to contact a D&K card manufacturing expert for more information.